CATALOGUES - Conveyor Idler Rollers

A.Composite idler roller

Composite roller material

The roller body and bearing housing are hot pressed through proprietary technology, mixed with polypropylene,

Quartz sand, high hardness powders etc total 16 kinds raw materials according to special formulation.

Structure drawing

1.roller shell 2.adhesive glue 3.pillow block 4.shaft

5.shaft cir clip 6.bearing 7.hole cir clip 8.seal

Advantages

1. T.I.R ≤ 0.1mm

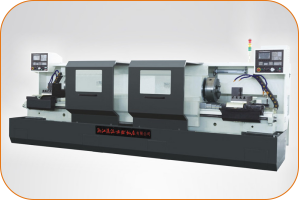

Double end boring machine

How do we do

Roller and bearing housing are by special double end boring machining.

The machine adopts double cutter, double system control, single knife adjustment, a clamping and cutting independent ends.

Non tolerance tight fit assembly of roller body and bearinghousing, processing concentricity is less than 0.02mm.

Why we do that

Small T.I.R, small vibration, conveyor runs smoothly and easily.Low power consumption and Long service life.

2. Low Noise Factor

Clients conducted a noise test on the metal roller and composite idler roller at the site of use of the conveyor CV371. At the belt speed of 6m / s, under normal working conditions, the metal roller noise was ≥ 80db; composite Roller was ≤ 70db.

Clients conducted a noise test on the metal roller and composite idler roller at the site of use of the conveyor CV371. At the belt speed of 6m / s, under normal working conditions, the metal roller noise was ≥ 80db; composite Roller was ≤ 70db.

Composite roller noise value Steel roller noise value

3.Super wear resistant

84pcs 152*333mm carry composite rollers and 32pcs 127*506 composite return rollers were installed in Conveyor CV371, on June, 2015. The speed for this conveyor is 6.0 m/s. After half year, all rollers shell wearing were < 0.2mm.

4.Anti-material sticky & Anti-static

Composite roller Steel roller

When the conveyor system which installed steel rollers running, some of the dust will often be attached to the surface of the rollers, not only corrosion rollers, and with the uneven thickness of dust, resulting in faster wear belt, deviation , Tearing and belt machine load increase and so on. As the composite rollers will not occur on the roll surface dust adhesion, effectively protect the conveyor belt, extending the life of the conveyor belt.

No sparks, More safe.

5.Anti-corrosion anti-acid and alkali

Especially for high humidity, high pH and strong corrosiveness harsh environment, such as chemical industry and wharf.

Tianjin Nanjiang coal terminal, humidity, high salinity, poor environment, the work piece temperature is about 50℃ in summer, steel rollers service life is less than half a year.

In 2014, we installed 200pcs 133 * 315mm carrying composite rollers, 80 pcs 133 * 950mm return

composite rollers. It is intact so far (December 2016)

6.High Anti-magnetic properties

In 2010, a loading conveyor belt of Tianjin Nanjiang Coal Terminal was installed composite conveyor rollers in the superconducting iron separator section.

The operation of the superconducting iron remover reaches 30,000GS, which has little effect on the operation of the composite rollers.

They are running well until now, the replacement rate is less than 1%.

Compared with the 6 months of stainless steel magnet roller working life, composite rollers can reduce cost 6 - 8 times.

B.Steel roller

1.plain roller ;2.triple roller ;3.side roller

Material of Steel roller --Pipe: Q235. --Shaft: 45# steel --Bearing Brand: HRB,C & U, SKF, FAG, NSK, etc. --Labyrinth seal: DTII labyrinth seal --Surface: powder coated, baked painting, spray painting | Specification: Dia: 60 76 89 108 102 114 127 139 159 178 219mm Belt Width: 450-2600mm Standard: JIS CEMA DIN AS Color: black red green yellow, etc, as the customers' requirement |

C. Rubber roller

1.Impact roller ;2.Disc rubber roller ;3.Rubber coated roller

Material of Rubber roller

--Pipe:Q235.

--Shaft:45# steel.

--Bearing Brand:HRB C&U SKF FAG NSK etc.

--Labyrinth seal:DTII labyrinth seal,

--Bearing Brand:HRB,C&U,SKF,FAG,NSK,etc.

--Surface:powder coated, baked painting, spray painting.

Summary of the roller size: | ||||

Standard External Diameter | Standard Inner Diameter | Length Scope | Bearings Type | |

mm | lnch | mm | mm | min-max |

89 | 3 1/3 | 60/ 50 | 170-3400 | 204 |

102 | 4 | 76 | 170-3400 | 204 205 |

108 | 4 1/4 | 89/76/60 | 170-3400 | 204 205 |

114 | 4 1/2 | 89/ 76 | 170-3400 | 204 205 |

127 | 5 | 89 | 170-3400 | 204 205 |

133 | 5 1/4 | 89/70/63.5 | 170-3400 | 204 205 |

140 | 5 1/2 | 89 | 170-3400 | 204 205 |

152 | 6 | 108/76 | 170-3400 | 204 205 206 305 306 |

159 | 6 1/4 | 108 | 170-3400 | 204 205 206 305 306 |

194 | 7 5/8 | 159/ 133 | 170-3400 | 205 206 207 305 306 307 308 |